PLC and DCS

PLC and DCS

Reliability, robustness, and precision.

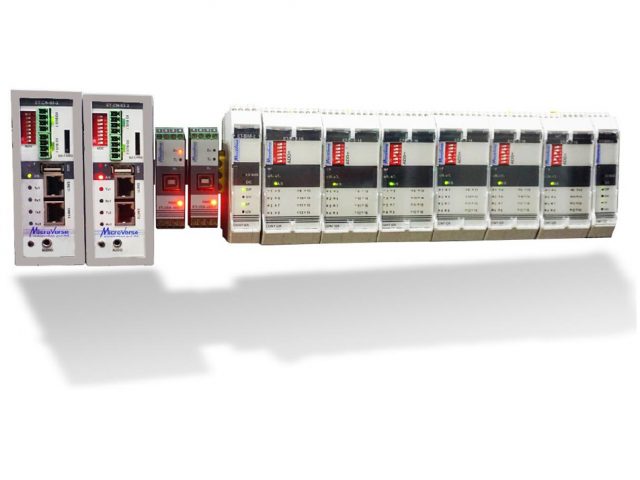

The Microverse PLC and DCS solutions offer the best of features along with reliability. These are typically used for process control of a wide range of critical mission-control automation applications.

Both PLC and DCS solutions have been deployed for applications from a very small number of IOs to systems with over 24,000 IOs. The systems are backed by Microverse’s own platform of software solutions that offer superior control and management along with extensive reports, trends, and alarm management suites.

- The systems are extremely compact and have low power consumption

- Voltage and current limited inputs meeting hazardous area requirements

- Can be configured as remote I/O based control system; savings in cabling costs

- True DCS Platform with common database for all the controllers in the network

- Special tools for development of logic for Batch / Sequential processes

The PLC and DCS function libraries come with in-built processes algorithms for managing chemical (batch and

continuous), power plants, oil and gas, ferro alloy, metallurgy automation, material handling, termination automation, water management, etc.

The Microverse DCS solutions in particular offer a wide range of advantages over traditional control systems. They provide centralized monitoring and control, improved automation, advanced alarm and event management, historical data logging, and remote access capabilities. These features enhance process efficiency, reliability, safety, and productivity.