Industry | Oil and Gas

Location

Year

Technology

Safety Systems

Cloud Monitoring

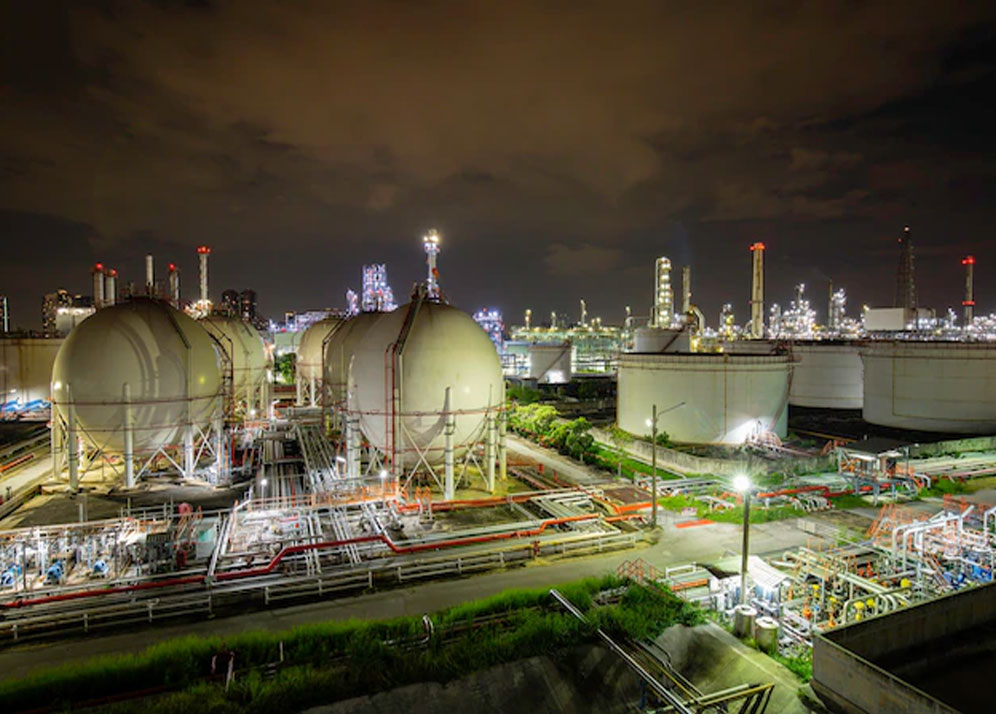

Microverse has worked with one of the largest companies in the energy sector for automation of their LPG storage, handling and bottling plant.

The system includes a DCS for the process automation, local stations, and a safety system. Microverse has also provided novel solutions based on IIoT for remote monitoring and for planning maintenance.

The customer has a major setup in Mangalore, located on west-coast of India in the state of Karnataka. This consists of:

- Two Jettys, which receive Propane, Butane or LPG from ships

- 7 km long Cross-country Pipeline through which liquid gas is transported to the Terminal

- Terminal for storage, blending, dispensing of LPG and a bottling plant

In the first phase of the project, Microverse automated the systems at the jetty terminal where Propane and Butane is blended. The blended gasses are then transported through a cross-country pipeline. Automation is provided for ratio control of Propane and Butane flow rates with density corrections for Temperature and Pressure. Appropriate safety interlocks for associated equipment are provided.

Microverse has also provided remote monitoring facility so that systems at Terminal and at Jetty can communicate with each other across the 7 k.m. long pipeline.

In the second phase, the processes at the main plant were automated.

The Terminal has the following major equipment

- 6 Nos. Horton Spheres; each of diameter of about 18 meter

- LPG Pump House #1. This has 5 LPG Pumps, 2 Compressors and Mercaptan Dosing System.

- LPG Pump House # 2. This has 5 Pumps and 1 Compressor.

- Gantries for Tanker Loading Facility

- Bottling Plant

- Fire Pump House. This houses 8 Diesel Engine driven pumps and 2 electrically operated Jockey Pumps

- Two Gas Detector Systems

- Two Fire Alarm Systems

- Deluge Valves and Sprinklers

- MCC for above equipment

Automation System supplied by MICROVESRE comprises of the following sub-systems

- Basic Process Control System (BPCS) configured around DCS – MICROSYS 3200 ET

- SIL 3 grade Safety System configured around HIMA make PLC

- Systems with HMI deployed at locations like LPG Pump House 1 and 2, Bottling Plant, Fire Water Pump House. These systems are also configured around MICROSYS 3200 ET

- Security and Administrative Support System (SASS), connected to Web Services

- Plant-wide redundant fiber optic communication cable network

The BPCS performs all the data acquisition, control, interlock functions, which typically include ROV line-ups for material receipt through cross-country pipe-line, storage in appropriate spheres, change-over of spheres, blending operations, mercaptan dosing, dispensing to gantries for unloading into tankers, dispensing to bottling plant etc.

The locally deployed systems support the BPCS for above operations. It may be noted that MICROSYS 3200 ET is designed to withstand harsh environment conditions up to 60oC ambient and being compact in size, can be readily enclosed in Flame-proof enclosures. HMIs provided with sub-systems provide necessary interface for the local operators.

The Safety System acts as an independent stand-alone system and provides final protection layer. Safety System communicates with BPCS over redundant MODBUS–IP Ethernet communication links.

Sub-system at Fire Water Pump House manages the 2 Jockey Pumps and 8 Diesel Pumps. The system performs automatic periodic testing of engines, batteries while maintain the header pressure of Fire Water line.

System has several third-party communication interfaces. These include:

- Enraf and E&H Make Servo Gauges fitted on the spheres

- Multi-Function Meters to acquire parameters related to energy consumption of various feeders in the plant

- Weigh-bridges

- Fire Alarm System

- Gas Detection System

- Anemometer

Microverse has also deployed the cloud platform – SASS. This platform integrates with DCS and provides following facilities to the users:

- Tablet and smart-phone applications for Permit Management. A variety of work permits are issued, validated, logged and supervised through with the help of this package.

- Lock-Out Tag-Out (LOTO) permits generated through SASS are interlocked with DCS to ensure higher level of safety.

- Plant Downgraded situations of different levels that are either generated automatically through DCS or entered manually are made available to concerned persons immediately.

- A novel ‘Shift Hand-over Procedure’ is implemented to ensure that all the concerns of outgoing Plant Operators are effectively understood by incoming Operators while taking the charge.

- All critical process parameters are made available to the users on their tablets and smart-phones.

- A large customized display is provided in the Admin Area to display all the relevant information regarding process parameters, permits, status of contractors, plant downgraded situations etc.

- Customized Report Generation package